Metallurgic plant appreciated benefits of eco-friendly Biomicrogel® coagulants in separation of spent cooling lubricants

Metallurgic plant appreciated benefits of eco-friendly Biomicrogel® coagulants in separation of spent cooling lubricants

One of the rolling mills in the production shop of the metallurgical plant, which will be discussed in this article, produces 40-50 m3 of spent cooling lubricants per day, which needs to be disposed of. Before the test, to separate the spent cooling lubricants, this workshop used sorption technology. After treating emulsion with a mineral sorbent, the oil content in the outlet water exceeds 60 mg/l, which does not allow such water to be returned to the technological cycle. Besides that, sorption treatment results in waste formation (watered, oil-contaminated aluminosilicate, in volumes reaching up to 10% of initial coolant), which was disposed of by dumping in landfill sites.

Thus the metallurgical plant has set the following goals:

1) Reduce the amount of generated waste that is passed to a special waste management service provider for final disposal

2) Lower the residual concentration of petroleum products in the clarified (purified) water to values of less than 40 mg/l

3) Decrease the negative impact on the environment in comparison with the existing technology used for processing cooling lubricants

The engineers of SPC BioMicroGel suggested the plant to use a set of reagents based on Biomicrogel® BMG-P2 coagulant to process the spent cooling lubricants for disposal. These reagents effectively capture any mineral, vegetable oils and petroleum products contained in the water. After separation of the oil-water mixture, the purified water can be returned to the technological cycle and reused. The separation process results in a small volume of precipitate of Hazard Class 4 and can be easily degraded to completely harmless components.

It is also important that BMG-P2 is based on natural polysaccharides – it is obtained by complex processing of vegetable raw materials: sugar beet pulp and apple pomace. The biodegradable coagulant BMG-P2 is completely environmentally friendly and yet easily separates even the most persistent emulsions. Table 1 shows the technical characteristics of the Biomicrogel® BMG-P2-03 coagulant used at the plant.

Table 1. Specifications of BioMicroGel® BMG-P2-03 coagulant

|

Property |

Value |

|

Physical form |

Powder |

|

Bulk density, g/cm3 |

0.8 |

|

Viscosity of the working solution*, mPA*s |

100-110 |

|

Ionic characteristic |

Amphoteric |

|

pH operating range |

2.8 – 8.0 |

|

Operating temperature range, °С |

0 – 85 |

* for 2% aqueous solution of BMG-P2-03

The BioMicroGel BMG-P2-03 coagulant is used as a 2% aqueous working solution; it binds (encapsulates) emulsified drops of oils and petroleum products and forms stable insoluble compounds. When further processing these compounds, a precipitate is formed, which is removed from the water by filtration or settling. SPC BioMicroGel not only supplies the BMG-P2-03 coagulant, but also offers a turnkey solution to this problem, including supply, installation and commissioning of the cooling lubricant separation plant as well as the supply of reagents. The company offers a range of cooling lubricant separation plants of various standard sizes depending on the required capacity (from 100 m3 per month to 10,000 m3 per month). The company can also design the plant to customer’s technical specifications, taking into account the individual features of the customer's technological cycle. The main elements of the plant are: a reagent dissolution and dosing station, a purification unit and a sludge volume reduction facility. The plant is equipped with control and monitoring devices, which are connected to a single automatic control system, therefore, it does not require a lot of manpower during operation.

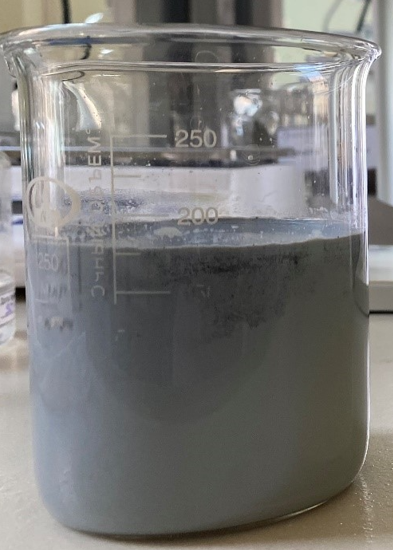

For tests carried out directly at the production site, the specialists of the plant provided a sample of the spent cooling lubricant emulsion (Fig. 1).

Figure 1. Original sample of cooling lubricant

The qualitative characteristics of the provided sample of the spent coolant emulsion are shown in Table 2.

Table 2. Specifications of the original cooling lubricant

|

Indicator |

Measuring unit |

Value |

|

Turbidity |

NFU |

above the measurement limit |

|

Content of oil products |

mg/dm3 |

10,000 |

|

pH value |

- |

8.0 |

According to the requirements set by the metallurgic plant, the residual content of oil products in clarified water should not exceed 40 mg/l, therefore, the required dosage of BMG-P2-03 coagulant was defined – 200 mg per liter of cooling lubricant.

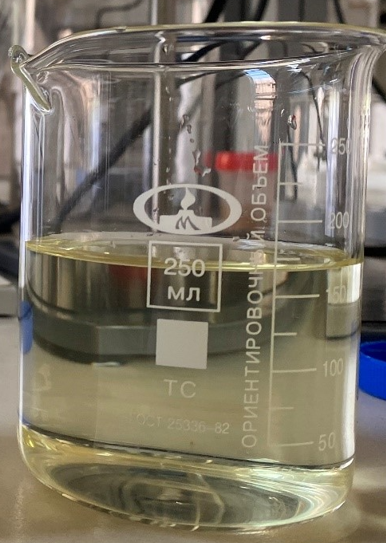

After BMG-P2-03 was added, the sample of spent coolant emulsion instantly decomposed, forming large floating flakes (Fig. 2).

Figure 2. Sample of cooling lubricant emulsion after adding the coagulant

Tests at a metallurgical plant were carried out at room temperature, but the BMG-P2-03 coagulant remains operational over a wide temperature range (from 0°С to +85°С). This makes the solution developed by SPC BioMicroGel more environmentally friendly and more economical than high-temperature coolant-disposal technologies, since it does not require additional heating of the emulsion. As a result, it reduces the cost of electricity or gas, and also decreases the emissions of hydrocarbons as well as acid and alkaline vapors into the environment.

A sample of clarified water was sent to an independent accredited analytical laboratory to confirm the quality of purification. The results of the analysis of the sample are shown in Table 3.

Table 3. Results of analysis after treatment

|

Indicator |

Unit |

Value |

|

Turbidity |

NFU |

7.5 |

|

Content of oil products |

mg/dm3 |

0.74 |

|

The volume of sediment after dehydration (from the original cooling lubricant) |

- |

2 |

The laboratory testing has shown that concentration of oil products in clarified water is 50 times lower than what the customer required. In this regard, the test report included a recommendation to reduce the dosage of the coagulant when commissioning this solution at the plant.

The cost of processing cooling lubricants using a solution based on the Biomicrogel® coagulant in the described case - even with dosages allowing to achieve residual content of petroleum products 50 times lower than required by customer - is 1150 rubles per 1 m3 of cooling lubricant (this cost includes not only the price of reagents, but also depreciation of the treatment plant equipment, labor cost, space rental fees, electricity and other expenses). In most cases, using an in-house solution based on the BMG-P2-03 coagulant is many times more profitable than handing over the spent coolant for processing to third-party companies: the cost of processing the spent emulsion using BMG-P2 varies from 350 to 2200 rubles per 1 m3 of cooling lubricant, depending on the composition of the emulsion and the performance of the treatment plant proposed as part of this solution, while the cost of its disposal by a third-party waste management company ranges from 3,500 to 6,000 rubles per 1 m3.

As a result, the implementation of this solution based on the BMG-P2-03 coagulant made it possible to achieve all the goals set by the specialists of the metallurgical plant:

1) Formation of floating, easily dehydrated sludge after treating the spent cooling lubricants with BioMicroGel® BMG-P2-03 coagulant allowed to reduce the volume of wastes from 10% (using the sorption purification technology) to 2% of the original cooling lubricant volume. Thus, the volume of wastes sent from the cooling lubricants treatment area for disposal decreased 5 times, bringing additional economic effect.

2) Reducing the concentration of oil products in clarified water to values of less than 40 mg/dm3 (compared to less efficient sorption technology, yielding more than 60 mg/dm3), Biomicrogel® BMG-P2-03 coagulant allows to achieve the residual content of oil products of 0.74 mg/dm3, making this process 50+ times more efficient than conventional technologies. During commissioning of the treatment plant, the engineers of SPC BioMicroGel suggested to reduce the dosage of the coagulant, which will lead to additional savings.

3) The fully recyclable sludge (waste for disposal), obtained during emulsion treatment, made it possible to eliminate waste dumping, and, together with a five-fold reduction in waste volumes, it led to a significant reduction of the negative impact on the environment, decreasing the carbon footprint in comparison with the sorption technology used at the plant earlier.

“From the environmental point of view, it is important that the coolant is separated without sorbent agents commonly used for such process. This removes the issues related to disposal of waste material, which is currently being dumped,” said Andrey Kryazhov, senior researcher at SPC BioMicroGel. “Besides that, the introduction of BMG-P2 coagulants into the technological process decreases the separation time, while also reducing the content of oil products in treated water to values even below the required specifications. Biomicrogel® is recognized as the world's best "clean technology" according to evaluation of the participants of the G20 Innovation League. It is also important that the use of BMG-P2 is fully consistent with the principles of decarbonization of the industrial sector and the “green” agenda formulated at the global level by governments and businesses.”

Today, no one has any doubts that humanity has no alternative to the ESG transformation (abbreviation for sustainable development of commercial activities with responsible attitude to environment, with E standing for environment; S standing for high social responsibility, and G – for high quality corporate governance). Having taken a course to drastically reduce the greenhouse gas emissions, the international community has set clear milestones: by 2030, the amount of greenhouse gas emissions should be at least half that of 2010, and by 2050 it should come to zero. Businesses, pushed towards carbon neutrality ("net zero") through taxes, emissions trading system, etc., no other way of development for themselves. No wonder the largest metallurgical corporations (such as ThyssenKrupp, BHP, Vale, Rio Tinto, Glencore, Anglo-American and others) announced that by 2030 they plan to reduce their СО2 emissions by an average of 30%, and by 2050 they intend to achieve carbon neutrality. The oil companies are not far behind. Plans to achieve net zero emissions by 2050 have been announced by ENI, BP, Shell, Total and Conoco Philips.

The effective and eco-friendly solution for cooling lubricants disposal offered by SPC BioMicroGel, which represents a set of reagents based on the Biomicrogel® BMG-P2 coagulant and a plant for mixing the working solutions, eliminates evaporation and does not require additional heating of the emulsion. As a result, it lowers down the cost of electricity or gas, and also helps decrease carbon emissions, allowing companies around the world to reduce their carbon footprint and comply with global ESG policies.

In addition to the metallurgical industry, the solutions from SPC BioMicroGel allow reducing CO2 emissions in all the scopes (Scope 1, Scope 2, Scope 3) in such applications as industrial wastewater treatment from oils and oil products, oil spill response, as well as in the production of vegetable oils.