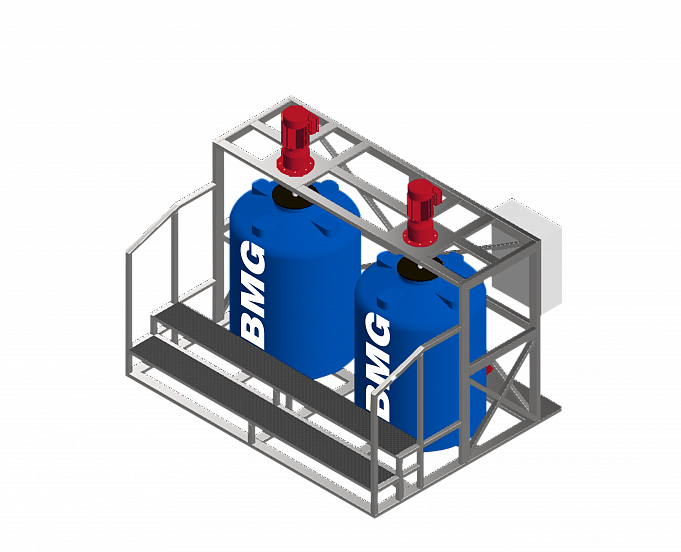

Preparation and Dosing Station BMG PDS-3000.2p

This equipment is designed for the preparation and dosing of the Biomicrogel® BMG-C4 oil extraction additive. The unit is designed for use in palm oil plants with a processing capacity of 90 to 120 FFB t/h (Fresh Fruit Bunches). The nominal capacity of this station is 2000 l/h of the solution with a concentration of 1% to 3%

Specifications

| Model | BMG PDS-3000.2p |

| Dry basis throughput | 60 kg/h |

| Solution throughput | 6000 l/h, with dissolution time of 30 minutes |

| pH value for a 3% water solution | 1.3–1.5 |

| Motor power of the metering pump | 0.37 – 1.1 kW |

| Capacity of the dosing pump 0.99 m3/h to 1.65 m3/h | 0.99 m3/h to 1.65 m3/h |

| Metering pump pressure | 0.3-0.4MPa |

| Effective volume of the tank used for the preparation and dosing of the BMG-C4 solution | 3.0 m3 |

| Number of tanks used for the preparation and dosing of the BMG-C4 solution | 2 pcs. |

| Stirrer type | Double deck paddle mixer |

| Stirrer rotation speed | 100 rpm |

| Overall dimensions | 3400mm(L) х 2800mm(W) х 2500mm(H) |

Learn more

This station for the preparation and dosing of the Biomicrogel® BMG-C4 oil extraction additive supports the following modes of operation:

- Automatic:

When in automatic mode, after theBiomicrogel® BMG-C4 oil extraction reagent solution is prepared, the station and the dosing pump are controlled by the turn on/off signal from the main transfer pump. - Manual:

In manual mode, after the Biomicrogel® BMG-C4 oil extraction reagent is prepared, the station and the dosing pump remain under the real-time control of a human operator.

The station for the preparation and dosing of the Biomicrogel® BMG-C4 oil extraction additive is shipped as a semi-knocked-down kit. The assembly and commissioning of the station is carried out locally by the customer under the supervision of representatives from SPC BioMiсroGel LLC. Prior to installation, preparatory works should be carried out by the customer to get the site ready for the permanent operation of the unit.

Application in solutions