Biomicrogel® reagents

for palm oil extraction

It will help you to produce more CPO

and reduce losses without major capital investments

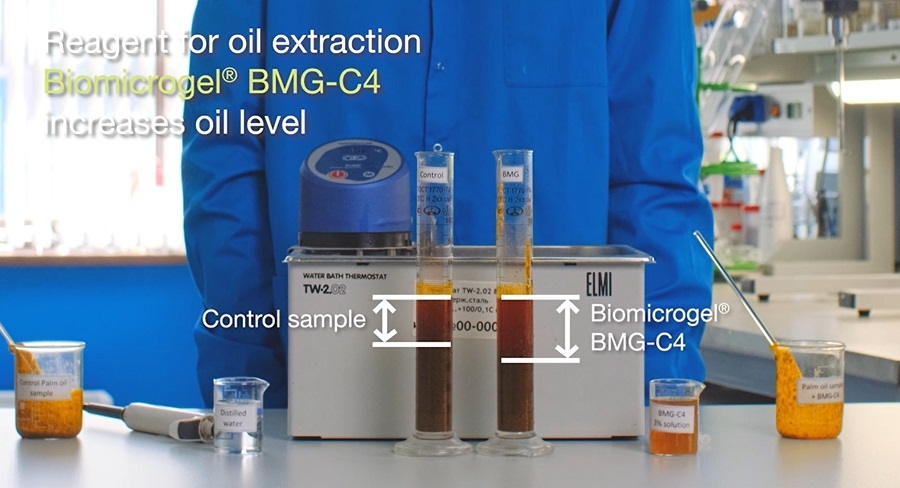

Increases OER more than 5%

Reduces oil losses more than 10%

Reduces water consumption up to 50%

Tasks to be solved

The process of producing palm oil has not changed in concept for the last 50 years.

The efficiency of the process can be improved due to:

The efficiency of the process can be improved due to:

Advantages

Biomicrogel® presents significant advantages for factories to increase productivity

without CAPEX investments and translates in attractive Economic Value Added effect.

without CAPEX investments and translates in attractive Economic Value Added effect.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)