Biomicrogels® reagents found effective in increasing palm oil production in Malaysia and Indonesia

Leading experts in palm oil extraction have recognized Biomicrogels® reagents as innovative to improve production efficiency and reduce costs at mills in Indonesia and Malaysia.

BMG products use in palm oil production in Malaysia and Indonesia

The Biomicrogels solutions were easily integrated in the technological process in the mills, increasing the CPO extraction rate by 5-15% and reducing the oil losses. With such indicators, businesses can expect an increase in profits of more than 500 thousand US dollars (about 7.6 billion Indonesian rupees) annually.

For today Biomicrogels Group signed contracts with 3 distributors in Malaysia and is now accelerating the shipment of BMG reagent to this country.

Biomicrogel® technology has been officially recognized by the Malaysian Palm Oil Board. The premier government agency of Malaysia confirms that "Biomicrogel® products form a single solution that easily integrates into the technological process positively impacts oil extraction by significantly and increasing productivity, reducing losses, and improving economic viability".

Sample before and after BMG-C4 application that increases oil extraction and reduces emulsion during production

Khairol Annuar Mohd Ali, Senior Manager at HB Laboratories, said: "At HB Labs, we're at the forefront of producing water treatment for offshore oil drilling platforms, specialising in separating oil from water before discharge into the sea. Leveraging our expertise, we extended our focus to palm oil mill effluent. We achieved exceptional results through rigorous testing and the development of our specialised equipment, High Efficiency Recovery Oil (HERO). However, when we integrated BMG, we witnessed a remarkable increase in oil extraction and moisture reduction. This success enabled us to secure long-term contracts with major clients in Malaysia."

BMG-C4 and BMG SPO reagents have proven to be efficient in addressing palm oil challenges in Malaysia and Indonesia. They have improved extraction efficiency, reduced waste and increased profits for palm oil mills.

Benefits of using Biomicrogels Group solutions

BMG-C4 and BMG SPO products are designed to improve palm oil extraction at all stages — from the clarification tank to centrifugation processes. They form submicron films around oil droplets and on the surface of fruit solids, helping to release the oil and float to the surface. This technology reduces extraction time, increases oil extraction and reduces oil losses in the effluent.BMG-C4 is a 100% natural product obtained from modified food cellulose. The reagent optimizes the stages of oil extraction and separation of oil from crushed particles and water. As a result of using the reagent in production, oil losses in the wastewater can be reduced by an average of 0.3 percentage points.

BMG-SPO reagent is a product for the extraction of sludge palm oil (SPO).

It improves the extraction process by up to 100%, so that companies could produce more, higher quality SPO in half the time without additional equipment. Also, application of BMG-SPO proved to decrease moisture in the SPO from 17% to less than 1%.

Given these benefits, mills can expect to comply with the eco-agenda and add more to their operating profits.

Igor Temirov, Business Development Director of Biomicrogels Group, explains: “The main challenges faced by palm oil mills in Malaysia are increasing OER (oil extraction rate), reducing production waste and financial losses. After a series of research and laboratory testing of the technology, we have achieved success with our products. They have shown significant results in increasing OER by 5-15% and reducing oil losses.”

Traditional palm fruit processing methods often result in production losses and large amounts of waste. Biomicrogels Group products can minimize oil loss in heavy and solid phases by more than 30%. This indicator reduces the negative impact on the environment and significantly reduces the costs of waste disposal and recycling.

Another challenge for the mills is to improve the efficiency of palm oil production. The Biomicrogels Group solution for SPO can reduce extraction time from 24 to 12 hours. By speeding up the process, the reagents also help reduce the cost of heating tanks with wood or diesel fuel as well as reduce water consumption.

Biomicrogels Group provides the BMG dosing station, BMG reagents as a complete solution.

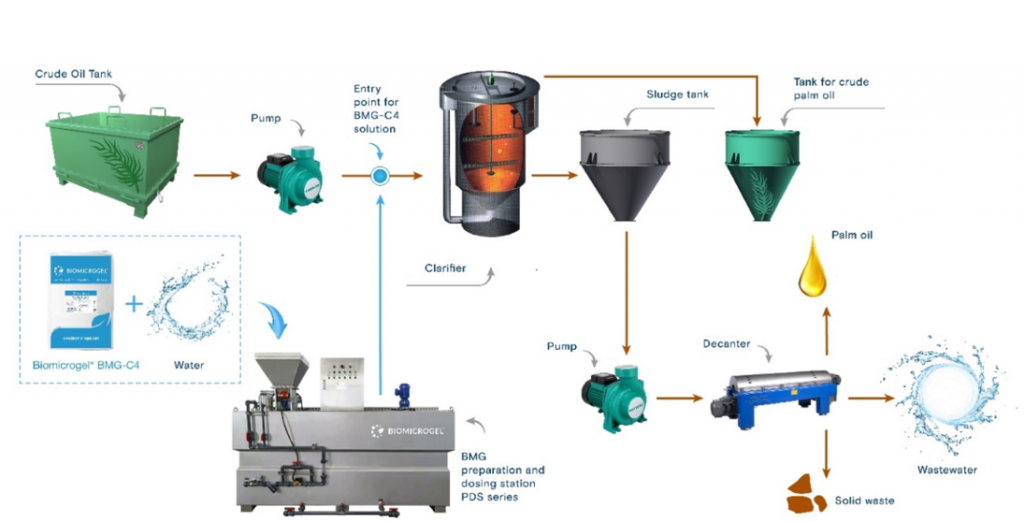

Biomicrogel® BMG-C4 application chart flow

The BMG equipment is easily integrated within one day in any production process with the minimum installation and running cost. The simplicity and adaptability of BMG technology to any mill capacity was successfully demonstrated at the mills from 15 tn/hr to 90 tn/hr capacity.

Palm oil production in Malaysia and Indonesia

Palm oil is a key ingredient in: food industry (production of butter, margarine, chocolate), cosmetic industry (production of soaps, creams, shampoos), pharmaceutical industry (production of medicinal products), as well as in the production of biodiesel fuel. It is used as a substitute for other oils and fats due to its stability, long shelf life and neutral taste.Palm oil production plays an important role in the economies of Indonesia and Malaysia. These two countries account for 87% of global palm oil exports and have more than 1,600 mills combined.

One of the mills in Indonesia and Malaysia

where Biomicrogels Group has implemented new technology

The process of extraction includes the following steps that may vary depending on the company scale, supply method and equipment configuration:

- Collection and transportation of raw materials. Palm fruit bunches are collected manually. They are then sent for processing.

- Preparation of raw materials. Fruit bunches processed in the sterilizer where they are heat treated to sterilize and soften the fruits before digesting and pressing.

- Oil extraction. The sludge diluted with water after the presses is going into clarification tank where the extraction is gradually taken place at temperatures of 85-95 C.

- Oil collection and waste processing. Extracted oil collected after the vacuum dryers and the remaining sludge goes to centrifuges or decanters to further collect CPO from sludge.

The described technology has remained relatively unchanged for 50 years. However, today the industry faces new challenges and changes. Problems arise with the waste disposal and increasing the production efficiency without negative impact on the environment.

Driven by growing demands for sustainability and consumer awareness, Malaysia and Indonesia are beginning to introduce new regulations and standards for palm oil production.

Mills are implementing sustainable extraction practices keeping in mind environmental protection and improving working conditions. This helps reduce the negative impact on nature. At the same time, companies are turning to environmental solution providers to increase productivity and improve efficiency of the businesses.

Secure solutions of Biomicrogels Group: how it works

Biomicrogels Group has accumulated significant experience in the field of water treatment. The team of 22 highly experienced engineers supported by the experts from R&D team can provide online and offline support for customers in any part of Malaysia and Indonesia where the BMG local teams can help with activities from lab tests to industrial trials and support of daily use of BMG products.

Cooperation with Biomicrogels Group will go through the following stages:- Select Palm Oil Mill for BMG trials.

- Conduct lab tests to demonstrate how BMG is working simulating extraction process on the lab scale.

- Gather technical data on the CPO oil content to determine the optimum BMG dosing,

- Installing the BMG dosing station and injection point after the CPO tank.

- BMG dosing station can be supplied within one month after placing an order and the BMG reagent can be delivered to a customer within 60-70 days.

- Our support team will provide BMG application specifications, operation manuals, laboratory test procedures.

The use of Biomicrogels Group products in palm oil production in Malaysia and Indonesia has great potential to improve profitability and mills KPIs. Mills will be able to make more money and improve their ESG profile by using Biomicrogels’ environmentally friendly solutions.