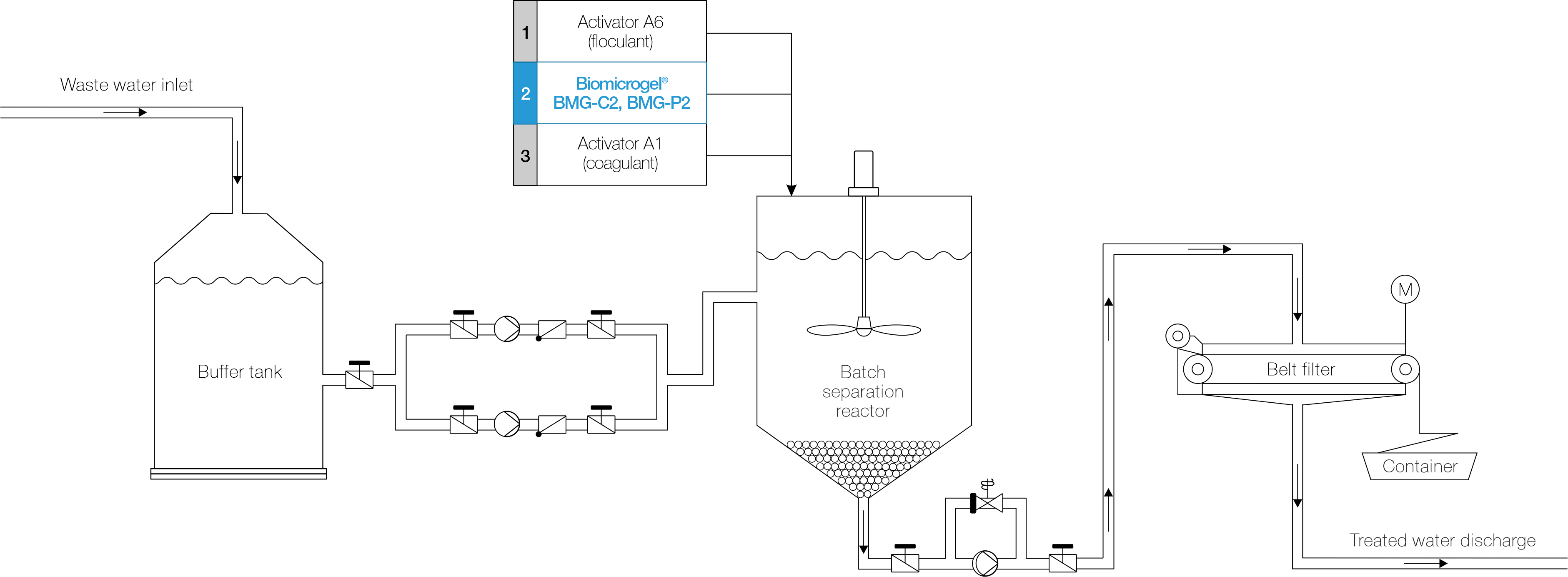

Reactor-type plant for the treatment of cooling lubricants

This plant is designed for cleaning cooling lubricants (cutting fluids) from oil products by treatment with a reagent followed by a filtration process. The plant produces purified water and a low-hazardous sludge.

* If a higher throughput is required, the company can develop a customized solution with several reactors or with vessels of a larger size

Specifications

| Plant throughput, m3 / day | Up to 100* |

| Occupied area, m2 | 70 to 150 |

| Volume of separation reactor, m3 | 5 to 12 |

| Rated power, kW | 5 to 20 |

| Rotation speed of the stirrer in the separation reactor, rpm | 100 |

| Tank material | Polyethylene, polypropylene, other materials on request |

Efficiency

Cost-effectiveness

Learn more

The purification process starts with the destabilization of the cutting fluid in the oxidation reactor by lowering its pH value with a solution of the 4A activator (acidic). Then the destabilized emulsion is subsequently treated with solutions of the Biomicrogel® BMG-P2 coagulant, A1 activator (coagulant), and A6 activator (flocculant). These reagents are mixed using an agitator installed inside the reactor. The batch separation reactor consists of a metal crate and a plastic reservoir placed inside it with a paddle stirrer installed. The tank is made of materials that can be used in contact with various substances, including aggressive ones. As a result of the dosing and mixing of the reagents, oil products are bound and a poorly soluble sediment is formed, which, after settling, is pumped out for further utilization. The clarified water produced as a result of separating the cooling fluid in the reactor is then discharged or is sent for further purification. The plant includes all the necessary technological equipment, piping for the technological equipment with the required shut-off and control valves, as well as devices used for monitoring and automating the technological processes. If necessary, the plant can be complimented with the following instrumentation: pH sensor, level sensor, phase separation sensor.

Application in solutions