Objective

Produced waters are a mixture of formation water and water injected in reservoir pressure maintenance system separated from the well production in the process of their conditioning, and water which is injected in reservoir pressure maintenance system.

Three common challenges often occur during treatment of produced water:

• Low efficiency of existing bottom settlement and produced water treatment technologies (concentration of petroleum products after treatment is 60-70 mg/l against required 50 mg/l max.)

• High CAPEX and OPEX incurred in terms of existing treatment technologies.

• Negative impact of Oil ad Gas Complex industries on environment.

Standard oil field water parameters

|

Parameter |

From |

Up to |

|

Petroleum products |

100 mg/l |

5000 mg/l |

|

Temperature |

5ºС |

90ºС |

|

Hydrogen Sulphide |

0 mg/l |

500 mg/l |

|

рН |

5 |

8 |

Key process indicators after introduction

|

Parameter |

Spilltex® membrane |

Biomicrogel® BMG-C2 |

|

Petroleum products |

<40 mg/l |

1-10 mg/l |

|

рН |

6.5-8.5 |

6.5-8.5 |

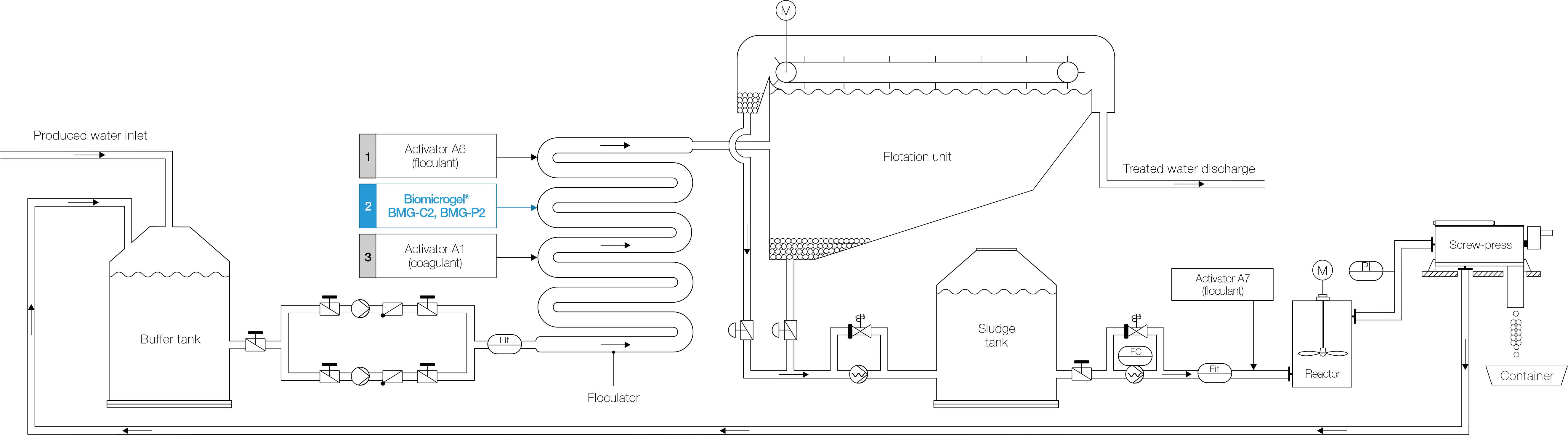

Oily waste water is fed into a pipe flocculator for chemical treatment by solutions of coagulant, flocculant Biomicrogel® BMG-C2 or coagulant Biomicrogel® BMG-P2 and flocculant based on polyacrylamide. The water treated by chemicals passes through a pipe flocculator for better mixing and distribution of chemicals in the waste water volume. As a result of the chemical dosing, oil products are bound and poorly soluble particles are formed. Further, the wastewater is sent to the flotation unit, where the pollutants as a flotation foam are removed due to the physicochemical treatment. The treated waste water is discharged by gravity from the flotation unit, and the separated flotation foam is fed to the screw-press for dewatering.

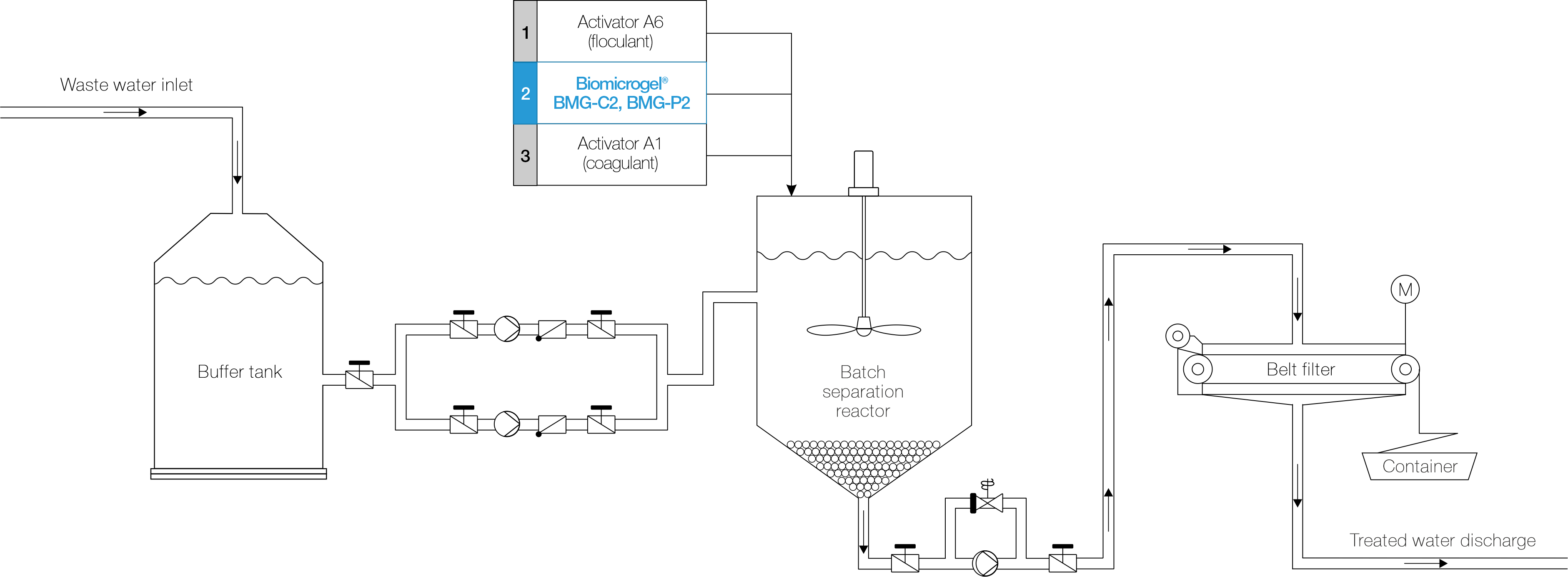

The technological scheme for the oily waste water treatment provides its accumulation and sequential processing in the separation reactor by solutions of the coagulant Biomiсrogel®BMG-P2, coagulant and flocculant based on polyacrylamide. As a result of the chemical dosing and mixing, oil products are bound and poorly soluble particles are formed. After the settling, the formed sludge goes to a belt filter for filtering, and the treated waste water is discharged by gravity.

Biomicrogel® coagulant BMG-P2 catch any mineral and vegetable oils, animal fats, and oil and petroleum products in water effectively, based on sweep- coagulation process.

They catch any mineral and vegetable oils, animal fats, and oil and petroleum products in water effectively, based on sweep- coagulation process.

After separation of oil-water mixture both treated water and removed petroleum products can be returned to the process cycle and re-used. Biomicrogel® coagulant BMG-P2 are well compatible with almost all flocculants based on inorganic salts of polyvalent metals cleaning water from suspended particles.

Biomicrogel® coagulant BMG-P2 catch any mineral and vegetable oils, animal fats, and oil and petroleum products in water effectively, based on sweep- coagulation process.

They catch any mineral and vegetable oils, animal fats, and oil and petroleum products in water effectively, based on sweep- coagulation process.

After separation of oil-water mixture both treated water and removed petroleum products can be returned to the process cycle and re-used. Biomicrogel® coagulant BMG-P2 are well compatible with almost all flocculants based on inorganic salts of polyvalent metals cleaning water from suspended particles.

Biomicrogel® coagulant BMG-P2 must be diluted in water using static mixer or other appropriate mixing device suitable for making homogeneous solution.

Biomicrogel® coagulant BMG-P2 are supplied as powder. They are packed in 25 kg polypropylene bags, and the bags are then placed on pallets. Pallet houses 20 bags – 500 kg of the flocculant.

Biomicrogel® coagulant BMG-P2 as solution are supplied in 1000 liters IBC containers.

Store the product in cool and dry place. Keep the entire protective packaging safe before using the product.

Guaranteed storage life in dry form – 24 months as of date of manufacture. To avoid hydrolysis or increase of microbial counts, fungi, hence resulting in deterioration, use the treatment solution within 14 days, if prepared on your own.

After the precipitation from water the Biomicrogel® BMG-P2 flocculant shall be disposed of in accordance with effective legislation.

The following FCCW Code is applicable: 7 23 301 02 39 4: “The sediment (sewage sludge) from the flotation treatment of oily wastewaters, containing less than 15% of petroleum products”.

Other solutions