Solution for increasing palm oil extraction

- Increases CPO production volume more than than 5%

- Reduces oil losses in heavy phase and solid more than 30%

- Increases oil extraction in empty fruit bunches more than 10%

Objective

The solution includes reagents, equipment,

and the expertise of our engineers, who can help you get set up

Reagent BMG-С4

for increasing the extraction of palm oil

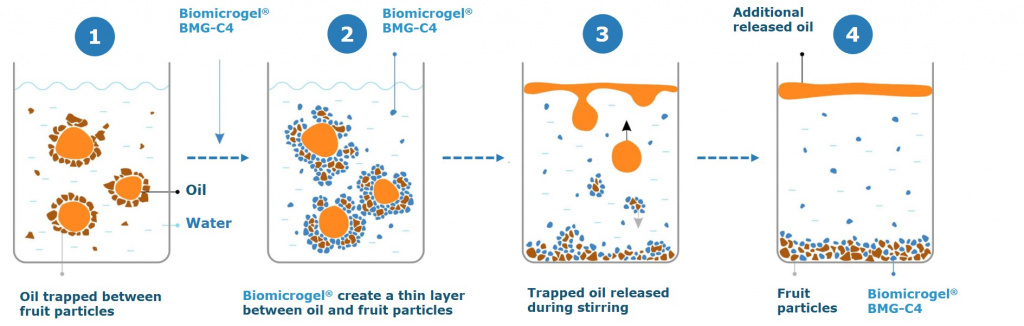

When BMG-C4 comes into contact with oil dropletson palm fruits which have been crushed in water

it forms a submicron film around them. This film helps

the oil to be released faster and in greater volumeAbout the product

How does BMG–C4 work

the reagent remains in the water and sludge

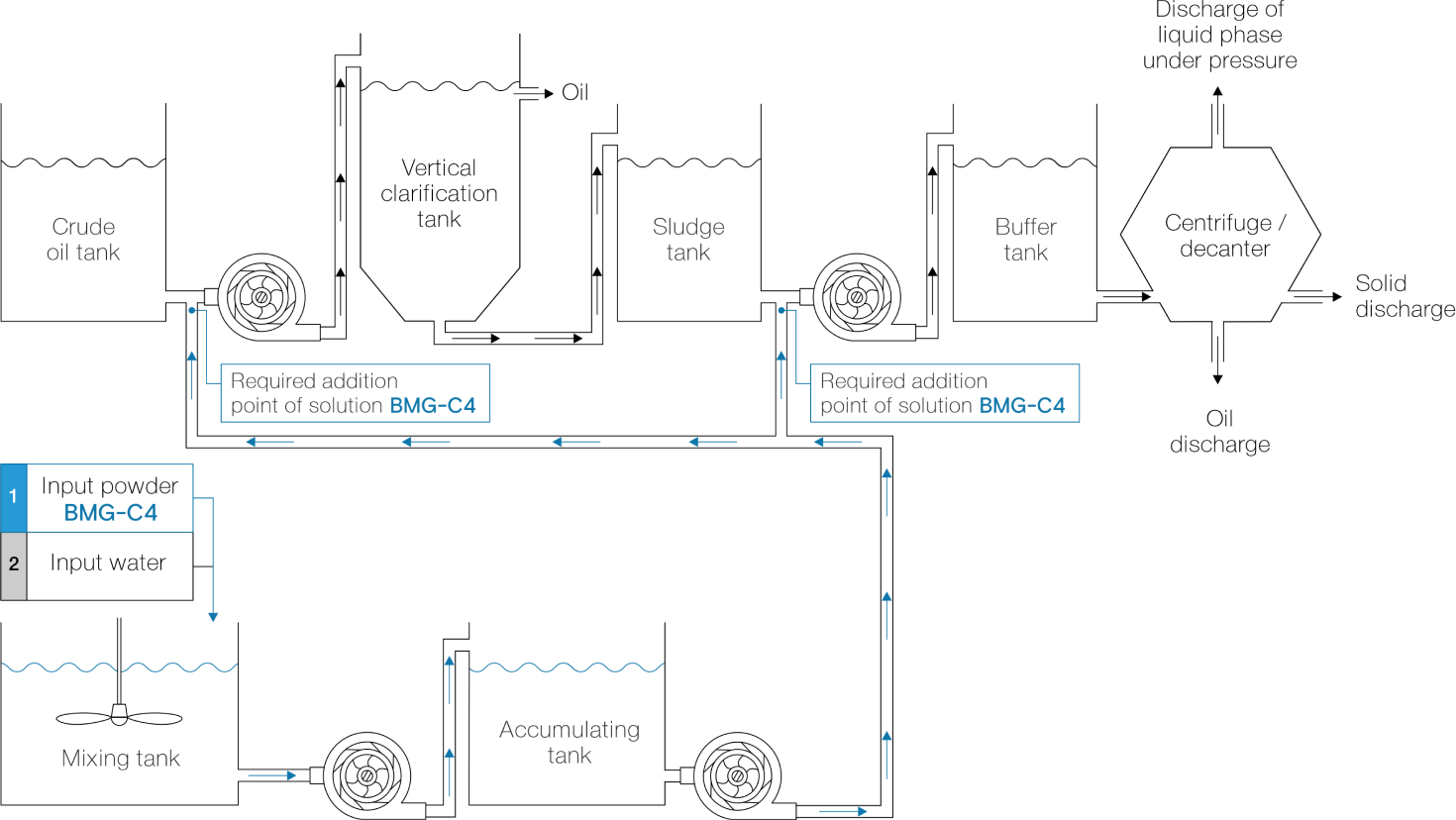

BMG PDS preparation and dosing station

In automatic mode it prepares, doses, and pumps a 3%solution of BMG-C4 through the client's system. About the product

reagent after a centrifugal pump that pumps unrefined palm oil into a clarifier.

How does the BMG solution

improve the efficiency of your mill

The process of producing palm oil has not changed in concept for the last 50 years.

We have just improved it so you can earn more due to:

crude palm oil (CPO)

the clarifier and reduced loss

on entry to the decanter

palm oil tank (COT) by 50% or more

mill effluent (POME)

Your mill will save

over $500,000 a year

after implementing the BMG solution

Why are we sure that our solution suits you?

showed an increase in oil extraction by up to 5-30% per hour

The BMG reagent is environmentally friendly and safe

BMG is made of beet and apple pulp, cellulose, starch etc. (CAS–number9004-32-4, EC–number 618-378-6). It is 100% biodegradable, safe

for people and the environment, and complies with ЕС № 1272/2008

of the oil or its characteristics

of the volume of oil content in palm fruits

easier. Even for palm-kernel oil

for the implementation of the solution

in the mill’s existing workflow

will increase the prime cost of processing

1 ton of FFB by just $2

.png)

Contact us today so that we carry out a test

at your mill and prove BMG’s efficiency

The advantages of collaboration with Biomicrogel®

Inhouse R&D center

More than 100 patents in 62 countries

Inhouse production

Regular participation in industry events

Laboratory and pilot tests

.png)

We work in Southeast Asia,

Europe, USA, and Brazil

Upon contact with drops of oil in the aqueous phase, BMG-C4 stabilizes at the oil-water interface forming submicron polymer films, displacing the drops of oil from the particles of the crushed crop, after which they rise to the surface.

Unlike the other Biomicrogel® modifications used as a sorbent, flocculant, or flocculating agent where the strength of films (microcapsules) is critical and must be maintained for a long time, in this case it is only necessary to ensure their short-term presence on the surface of the solid particles, ensuring the oil is separated from the solids and rises to the surface of the water. After the process is completed, BMG-C4 is distributed in the aqueous phase and over solids.

Upon contact with drops of oil in the aqueous phase, BMG-C4 stabilizes at the oil-water interface forming submicron polymer films, displacing the drops of oil from the particles of the crushed crop, after which they rise to the surface.

Unlike the other Biomicrogel® modifications used as a sorbent, flocculant, or flocculating agent where the strength of films (microcapsules) is critical and must be maintained for a long time, in this case it is only necessary to ensure their short-term presence on the surface of the solid particles, ensuring the oil is separated from the solids and rises to the surface of the water. After the process is completed, BMG-C4 is distributed in the aqueous phase and over solids.

Upon contact with drops of oil in the aqueous phase, BMG-C4 stabilizes at the oil-water interface forming submicron polymer films, displacing the drops of oil from the particles of the crushed crop, after which they rise to the surface.

Unlike the other Biomicrogel® modifications used as a sorbent, flocculant, or flocculating agent where the strength of films (microcapsules) is critical and must be maintained for a long time, in this case it is only necessary to ensure their short-term presence on the surface of the solid particles, ensuring the oil is separated from the solids and rises to the surface of the water. After the process is completed, BMG-C4 is distributed in the aqueous phase and over solids.

BMG-С4 is used in the form of a 3% solution.

In order to prepare the BMG-C4 solution for use, it is necessary to use the special BMG PDS series preparation and dosing equipment while following the instruction manual for BMG-C4

BMG-С4 is supplied as powder.

It is packed in 25kg polypropylene bags; the bags are then placed on pallets. One pallet carries 20 bags, which is 500 kg of product.

To avoid hydrolysis or the growth of bacteria and fungi, resulting in a deterioration of the solution, use the BMG-С4 solution within 7 days of its preparation.

BMG-C4 is stored in the manufacturer’s package in ventilated warehouse premises protected from direct sunlight at a relative humidity of no more than 70% at a temperature not exceeding 37°C in conditions that exclude dust penetration and precipitation. The guaranteed shelf life of the packaged product is 24 months as from the date of production.

When the solution is prepared, it creates an environment for the growth of airborne or aquatic bacteria and fungi. Always add a biocide in storage areas where this process is taking place.

It is recommended to use isothiazoline-based biocides in the proportion of 700 ppm of agent per volume of water. Equipment for the preparation of the BMG-С4 treatment solution as well as any containers for its storage and any pipelines used should be pre-flushed and disinfected.

BMG-С4 shall be disposed of in accordance with effective legislation.

Other solutions